Newest trend is a term that refers to one thing which is latest in the market. Because of Blac Label’s huge reputation and demands, the label was expanded to accomodate not only the wants of men for vogue and magnificence, but also for the ladies that craves a brand new thing that could set a brand new pattern for women’s style. These collections of Blac Label clothes strains also contains equipment such as caps, bracelets, wallet chains, and many more.

Newest trend is a term that refers to one thing which is latest in the market. Because of Blac Label’s huge reputation and demands, the label was expanded to accomodate not only the wants of men for vogue and magnificence, but also for the ladies that craves a brand new thing that could set a brand new pattern for women’s style. These collections of Blac Label clothes strains also contains equipment such as caps, bracelets, wallet chains, and many more.

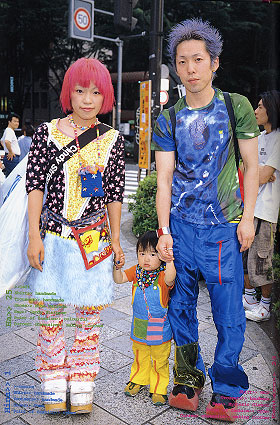

As we speak, many mother and father gown their children in a lot the same method as they costume themselves. Youngsters put on denims or khaki pants, a tee shirt, and sneakers just like mom and pa. These present styles are all about consolation. In the past, the high style of the rich lessons was not created for comfort. Removed from it.

Minimalist footwear is a relatively new pattern in trainers that may or might not show you how to. These kind of footwear provide much less cushioning than normal trainers. A lot of them have a smaller heel, which makes your foot more flat as you land on the bottom.

Workout gear will also get in on this pattern. In late 2019, Nike launched a brand new basketball shoe designed to be easier to get on and off for individuals with disabilities. The lace-much less Air Zoom UNVRS were designed in partnership with professional basketball player Elena Delle Donne and inspired by her older sister Lizzie, who has cerebral palsy and autism.

Keep in mind that style jewellery is indispensable this season, not only as a result of it’s the vogue trend, however as a result of it reaches an historic excessive in inventive beauty. On the subject of purses, outsized is the name of the game. For footwear, it is peak and metallics. So, for summer time 2007 big and daring is the model. Combine and match accessories with the easier developments in clothing this summer time and you’ll be adorning your inner trendsetter! Most significantly, have fun with playing with integrating among the summer season 2007 style accessory traits into your wardrobe.…

Next week’s London Fashion Show hosted by Burberry shall be photographed by the style company completely with the brand new camera on the iPhone 5s, Burberry and Apple announced tonight The corporate will use the iSight digital camera in the iPhone 5s to seize and share photos and video before, during and after the runway present in London on Monday, September sixteen. She has nice legs in excessive heels. They are lengthy and comely. She does not seem like the sort that may spend loads of time figuring out but her legs are nicely toned and slim anyway. She is likely one of the most fashionable celebrities, at all times sporting outfits and excessive heels that intensify her tall and slim physique. Some ladies do not need good vogue sense or do not care within the entertainment discipline, however clearly Vigorous spends time making sure she seems nice.

Next week’s London Fashion Show hosted by Burberry shall be photographed by the style company completely with the brand new camera on the iPhone 5s, Burberry and Apple announced tonight The corporate will use the iSight digital camera in the iPhone 5s to seize and share photos and video before, during and after the runway present in London on Monday, September sixteen. She has nice legs in excessive heels. They are lengthy and comely. She does not seem like the sort that may spend loads of time figuring out but her legs are nicely toned and slim anyway. She is likely one of the most fashionable celebrities, at all times sporting outfits and excessive heels that intensify her tall and slim physique. Some ladies do not need good vogue sense or do not care within the entertainment discipline, however clearly Vigorous spends time making sure she seems nice. Again and again, the message society sends us is that a lady’s magnificence ought to decide her value. One of the developments of this 12 months are handmade pom-pom bracelets, which may be accessorized to the spring and summer time garments. These things come in several shade, especially in the shades of the 12 months, and they might be matched with the color of the bags, and even with the other accessories. Some designers had inspired from the nature, and created bracelets, which function stars and animals, and they’re essentially the most suitable ones to be worn by women who like to dress simple, and to face out with the help of their jewelries. In case you are a keen about handmade jewelries, it is best to know that many of the fashions listed below are custom-made and tailored by designers, and you should purchase them from their on-line shops.

Again and again, the message society sends us is that a lady’s magnificence ought to decide her value. One of the developments of this 12 months are handmade pom-pom bracelets, which may be accessorized to the spring and summer time garments. These things come in several shade, especially in the shades of the 12 months, and they might be matched with the color of the bags, and even with the other accessories. Some designers had inspired from the nature, and created bracelets, which function stars and animals, and they’re essentially the most suitable ones to be worn by women who like to dress simple, and to face out with the help of their jewelries. In case you are a keen about handmade jewelries, it is best to know that many of the fashions listed below are custom-made and tailored by designers, and you should purchase them from their on-line shops. Trend designing has always been a well-liked alternative of younger men and women all over the world. As we speak there are a whole bunch of particular person physique positive Instagrammers finding their voices and sharing vulnerabilities, struggles and moments of triumph on their personal pages. Lots of them are growing into their own manufacturers and have the opportunity to teach media retailers, writer books and even create their own clothing lines. However as @bodiposipanda creator and writer Megan Crabbe explains, the BoPo motion initially started with group pages like @pizzasisters4lyfe and @effyourbeautystandards , which featured inspirational quotes, colourful, various drawings and an array of bodies of various shapes, sizes and shades from contributors everywhere in the world.

Trend designing has always been a well-liked alternative of younger men and women all over the world. As we speak there are a whole bunch of particular person physique positive Instagrammers finding their voices and sharing vulnerabilities, struggles and moments of triumph on their personal pages. Lots of them are growing into their own manufacturers and have the opportunity to teach media retailers, writer books and even create their own clothing lines. However as @bodiposipanda creator and writer Megan Crabbe explains, the BoPo motion initially started with group pages like @pizzasisters4lyfe and @effyourbeautystandards , which featured inspirational quotes, colourful, various drawings and an array of bodies of various shapes, sizes and shades from contributors everywhere in the world. Hey guys, bear in mind paracord bracelets? It is very important just be sure you are trying to maintain your jewelry as safe and secure as possible. Particularly in case you have jewelry that’s really priceless to you, or that’s expensive. With these tips, it is possible for you to to make sure that you know learn how to preserve your gold, diamond and gemstone jewelry protected.

Hey guys, bear in mind paracord bracelets? It is very important just be sure you are trying to maintain your jewelry as safe and secure as possible. Particularly in case you have jewelry that’s really priceless to you, or that’s expensive. With these tips, it is possible for you to to make sure that you know learn how to preserve your gold, diamond and gemstone jewelry protected. One of the largest problems many jewelry shops have with repair providers isn’t overcharging, but undercharging. Girls prefer diamond rings , bracelets, appeal and necklaces and so forth. for special day equivalent to engagement and marriage ceremony, ladies select precious stones jewelry. Males principally put on massive pendants and large rings with a cross or some other symbolic signal. Silver chains are also greatest for males.

One of the largest problems many jewelry shops have with repair providers isn’t overcharging, but undercharging. Girls prefer diamond rings , bracelets, appeal and necklaces and so forth. for special day equivalent to engagement and marriage ceremony, ladies select precious stones jewelry. Males principally put on massive pendants and large rings with a cross or some other symbolic signal. Silver chains are also greatest for males. Mustard seed necklaces are very unusual yet very tasteful Christian jewelry. Extra Hardware: At the perfect of times, many people have a minimum of a couple of screws free, or a nail or a bolt or two. For those who’ve got an extra couple of drawers available in your jewelry boxes, you would commit them to storing the extra hardware you accumulate from putting furniture or toys collectively, or just the ones you buy because you assume you want them after which need a place to place them that may hold them from being on the floor and then being stepped on by your bare foot. Jewelry instances are nice for protecting small issues like earrings from going far and wide, so they may keep all of your nuts and bolts squared away also.

Mustard seed necklaces are very unusual yet very tasteful Christian jewelry. Extra Hardware: At the perfect of times, many people have a minimum of a couple of screws free, or a nail or a bolt or two. For those who’ve got an extra couple of drawers available in your jewelry boxes, you would commit them to storing the extra hardware you accumulate from putting furniture or toys collectively, or just the ones you buy because you assume you want them after which need a place to place them that may hold them from being on the floor and then being stepped on by your bare foot. Jewelry instances are nice for protecting small issues like earrings from going far and wide, so they may keep all of your nuts and bolts squared away also. In relation to gold jewelry, diamonds and gem stones, there are so many people that get theirs stolen. The most typical problem I see in costume jewelry is with the stones – rhinestones, crystal, glass or plastic, they might come out of their settings, be unfastened, or crack or boring. Older pieces could also be set with glue that has dried and let the stone fall out. It’s vital to use the correct of adhesive, and to not use too much. Krazy Glue or Super Glue is not really helpful, as it could break down when connected to glass. Super Glue may be especially damaging to vintage pieces – a film may develop if it reacts to old steel and plating. If you get it on the floor of the stone, it is difficult to take away. By no means use hot glue – it may possibly expand and contract with temperature changes and may crack the jewelry or loosen the stone. The most effective adhesive to use can be one designed specifically for jewelry, which might be found in craft shops and on jewelry provide internet sites.

In relation to gold jewelry, diamonds and gem stones, there are so many people that get theirs stolen. The most typical problem I see in costume jewelry is with the stones – rhinestones, crystal, glass or plastic, they might come out of their settings, be unfastened, or crack or boring. Older pieces could also be set with glue that has dried and let the stone fall out. It’s vital to use the correct of adhesive, and to not use too much. Krazy Glue or Super Glue is not really helpful, as it could break down when connected to glass. Super Glue may be especially damaging to vintage pieces – a film may develop if it reacts to old steel and plating. If you get it on the floor of the stone, it is difficult to take away. By no means use hot glue – it may possibly expand and contract with temperature changes and may crack the jewelry or loosen the stone. The most effective adhesive to use can be one designed specifically for jewelry, which might be found in craft shops and on jewelry provide internet sites. Searching for the women trend dresses may very well be real enjoyable in addition to one of the rewarding experiences for the customer. The second island, “île Saint Honorat” is house to a neighborhood of Cistercian monks in the Lérins Abbey Guests may attend some companies and uncover the merchandise made by the monks. Another place to see: the fortified monastery. Constructed within the Eleventh Century, this historic building is a wonderful instance of the structure of the Center Ages. Along with the fortifications, you may see the two cannonball furnaces at either end of the island.

Searching for the women trend dresses may very well be real enjoyable in addition to one of the rewarding experiences for the customer. The second island, “île Saint Honorat” is house to a neighborhood of Cistercian monks in the Lérins Abbey Guests may attend some companies and uncover the merchandise made by the monks. Another place to see: the fortified monastery. Constructed within the Eleventh Century, this historic building is a wonderful instance of the structure of the Center Ages. Along with the fortifications, you may see the two cannonball furnaces at either end of the island. Layered hairstyles are among the most popular and elegant hairstyles within the style world today. It’s possible you’ll be happy to listen to necklaces have made a great comeback this season. Necklaces are statement pieces this season, they are going to; variety from the very lengthy and daring in design, to simple, with multiple long layers. As mentioned heat colors are especially outstanding in jewelry designs. If you happen to love vintage, pull out your antique jewelry. Mix previous with new, it’s a great look. Actually, a bracelet will be thick or thin. If skinny you will see them stacked. Bracelets can be colorful or monotone, mixing kinds, and colors are an enormous development. The designers are showing some great artistic kinds. Especially; with their bangles, you will note wrap bracelets with wire, adorned with beads and pure fibers, even fabric. So, jazz up your wardrobe with masses bracelets this season.

Layered hairstyles are among the most popular and elegant hairstyles within the style world today. It’s possible you’ll be happy to listen to necklaces have made a great comeback this season. Necklaces are statement pieces this season, they are going to; variety from the very lengthy and daring in design, to simple, with multiple long layers. As mentioned heat colors are especially outstanding in jewelry designs. If you happen to love vintage, pull out your antique jewelry. Mix previous with new, it’s a great look. Actually, a bracelet will be thick or thin. If skinny you will see them stacked. Bracelets can be colorful or monotone, mixing kinds, and colors are an enormous development. The designers are showing some great artistic kinds. Especially; with their bangles, you will note wrap bracelets with wire, adorned with beads and pure fibers, even fabric. So, jazz up your wardrobe with masses bracelets this season.